BSc Remote Medicine at Hackspace: Prototyping a low cost, continuous oxygen saturation probe

Vicky Earl and Ellie Morgan completed a 15 week project with BSc Remote Medicine at Hackspace, and both worked on developing a device to monitor oxygen saturation to predict Acute Mountain Sickness (AMS) in the wearer.

By Vicky Earl, BSc Remote Medicine '21, Faculty of Medicine and Ellie Morgan, BSc Remote Medicine '22, Faculty of Medicine

In the spring and summer 2021 Hackspace hosted several undergraduate students from BSc Remote Medicine to complete a 15 week project designing, prototyping and building devices related to biological sensing and validation. Vicky Earl and Ellie Morgan both worked on developing a prototype to monitor oxygen saturation, which could be used to predict Acute Mountain Sickness (AMS) in the wearer. Below they share their experiences working on their projects with Hackspace.

The project

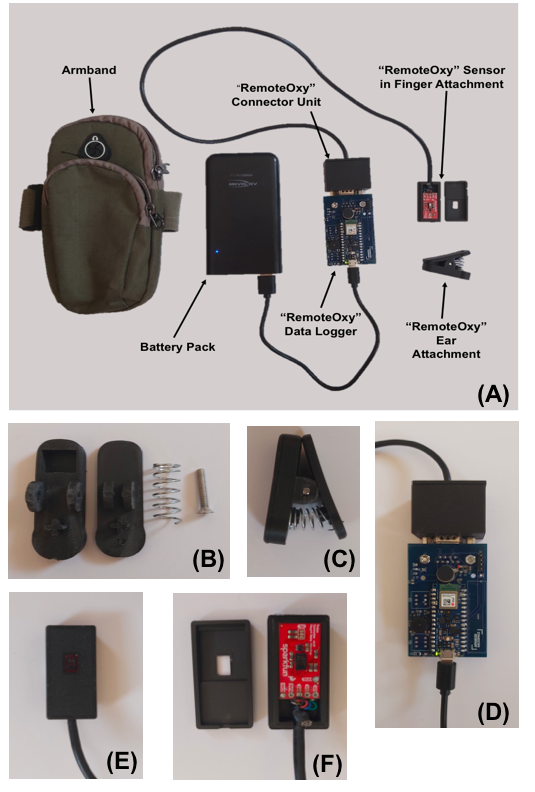

Vicky: At high altitude, some individuals suffer from acute mountain sickness (AMS). There is evidence to support that the continuous monitoring of arterial oxygen saturation could be used to predict who would develop AMS. These is currently no device suitable for the remote environment which is able to do this. I was aiming to design and prototype a low cost, continuous oxygen saturation probe which could transmit data wirelessly and in real time to a mobile device.

Going into the project I was very unsure about what to expect. I was aware that there was a lot of new skills that I would have to learn quickly but no clear idea of what the final design would look like. Following an initial design and brainstorming process, several off the shelf sensor components were purchased. In addition, PCBs were designed using KiCad EDA and printed externally, the casing designed on Autodesk 360 and printed using the Hackspace’s Markforged 3D printers and the device coded for using Arduino IDE. Once built, the prototype was tested during a field trip to the Lake District to assess its suitability for the remote environment.

Ellie: The project was to prototype an affordable, wearable, monitoring device, initially focusing on HR and SpO2 using dual wavelength photoplethysmography. I then aimed to compare this against a medically validated device to determine its accuracy. To complete the project, I needed to learn skills in electronics and coding and to produce a prototype device that could be developed further in the future. The project also has involved design and manufacturing, including learning skills in coding and electronics as well as 3D CAD design and 3D printing.

Developing a device to monitor oxygen saturation to predict Acute Mountain Sickness (AMS) in the wearer

The Hackspace experience

Vicky: At the Hackspace, there was always someone on hand to demonstrate how to use equipment or software programs, meaning it was possible to achieve a lot in a short period of time. Furthermore, the fellows gave valuable feedback on your work as and when you were doing it. The fellows provided a good sounding board to bounce ideas off and provided really useful input as to how I might overcome any challenges I was having. It was also fascinating to hear about the other projects they were involved with and I felt I developed my problem solving skills through discussions I had with them on a wide range of issues.

I have learnt so many new skills throughout this project such as 3D modelling, basic coding with C++, PCB design and soldering just to name a few. In addition to these technical skills, I gained a greater understanding of how the prototyping process works and how best to tackle problems when they arise.

I was very apprehensive about this project at the start as I felt very underprepared, however the Hackspace team were so welcoming that I soon felt very comfortable in new environment. There was always someone around to ask a question if you were unsure of how something worked. Dr David Pitcher acted as a fantastic supervisor and mentor throughout the project, going above and beyond to support me and help guide me when I was unsure of how to tackle a problem.

“The Hackspace team were so welcoming that I soon felt very comfortable in new environment. There was always someone around to ask a question if you were unsure of how something worked.” – Vicky Earl

Ellie: Without the help of the Hackspace fellows the project would have been impossible for me! Dr Pitcher assisted in all aspects of the project and was an inspiring supervisor. I have learnt a host of new skills including coding, electronics, soldering, CAD design, 3D printing, and data analysis.

The Hackspace was incredibly supportive throughout the whole project. My supervisor was extremely dedicated to the project answering questions out of office hours to ensure we had a product on time. I was never afraid to ask for help even though my skills before the project were basic and I would often get stuck on simple tasks. The other Hackspace fellows Harry and David were also keen to help if they saw me struggling. All fellows have expertise in different fields. Dr Pitcher’s expertise in coding and electronics was essential to the success of the project. The facilities were available when needed and any extra parts needed to the device were ordered in as soon as possible. Overall, the staff at the Hackspace are very approachable and I thoroughly enjoyed working in the environment. I learnt so many new skills which will be invaluable in my future career.

The biggest achievement

Vicky: A memorable achievement was receiving my manufactured PCBs back knowing that I was involved in their design, especially as I had not even known what a PCB was four weeks prior. In addition, it was great to be able to bring the prototype back from the Lake District knowing it had survived two weeks of field testing.

Ellie: Designing and manufacturing the device.

Challenges and set backs

Vicky: The limited time frame for the project meant that the device had to be continuously adjusted and simplified, particularly as the Covid-19 pandemic greatly increased lead-in times for some parts. This required me to remain flexible and stay calm as deadlines approached much faster than I would have ideally liked.

Ellie: There were many set-backs which were made worse by long lead times due to Covid-19 which made progress slow at times. However every challenge was problem solved effectively due to the expertise of my supervisor and his commitment to help.

My advice to others

Vicky: Definitely to just go for it. The Hackspace team are so friendly and approachable so it is a great learning environment and is be a really fun experience.

Ellie: Be realistic about what you will achieve in the time you have. Enjoy the experience as it goes by more quickly than you would like.

What’s next

Vicky: I have gone back into my clinical medicine teaching as I complete my 5th and 6th years of medical school. I still have a very strong interest in high altitude and remote medicine and so will continue to look out for any opportunities to pursue these, with a new found confidence in taking on entrepreneurial and design projects.

“When it comes to the skills that I have learnt with the Hackspace… I will continue to be inspired by technological advancement in medicine. This will surely compete with my love for clinical practice to make me a more rounded medical professional.” – Ellie Morgan

Ellie: I will finish my medical degree next year and then I aim to do a diploma in tropical medicine with the intention to work abroad. I am aware that MSF encourage medical innovation and have grants for research. This may be the next step for me when it comes to the skills that I have learnt with the Hackspace. I will continue to be inspired by technological advancement in medicine. This will surely compete with my love for clinical practice to make me a more rounded medical professional.

Edited for clarity by Rebecca Covey