COVID-19 Snorkel Respirator project

Principle Investigators: Dr Ricardo Petraco & Dr David S. Pitcher

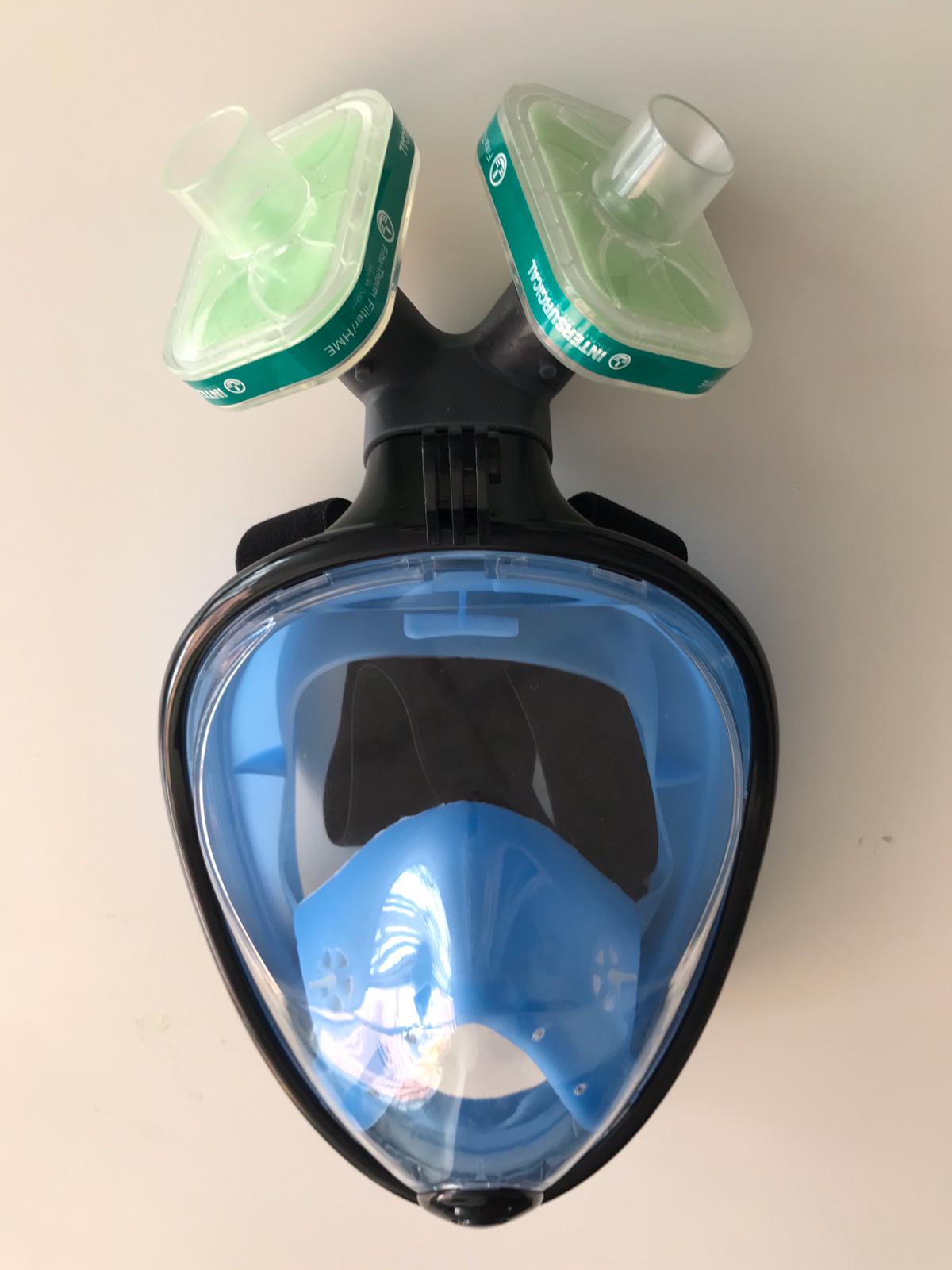

In response to the COVID-19 outbreak, Imperial College London’s Advanced Hackspace have collaborated with Imperial College Healthcare NHS Trust to design adaptors to convert currently available 3M respirators, as well as full face snorkels to fit the Heat and Moisture Exchanger (HME) filters available in hospitals.

With Personal Protective Equipment (PPE) shortages medical personnel have been under protected when treating patients during the COVID-19 crisis.

Our designs adapt full-face snorkels into respirators with the use of adapters to fit HME widely filters available in hospitals.

The adapters have been designed to utilise minimal amounts of material and with minimal supports to reduce print and clean-up times. We recommend them to be printed using SLA, SLS & DLP additive manufacturing technologies.

Benefits

- Utilises HME filters currently readily available in hospitals

- Snorkels, 3M respirators and printed adaptors can sterilised and re-used

- Full-face snorkels allow for more robust covering of eyes, nose and mouth than current mask and visor PPE

- Designs allow more options for those that fail mask fittings of disposable masks

- Modification is non-permanent with units able to be returned to standard functional use.

- Eco-friendly and re-usable reducing waste of disposable masks and visors

The opensource designs below have been tested using a FormLabs Form 3 using Tough 2000 resin with a z resolution of 100 μm.

We highly recommend using SLA, Digital Light Processing (DLP) or Selective Laser Sintering (SLA) manufacturing as the forces on Fused Filament Fabrication (FFF) models may cause delamination and leakages. Changes in the print material or process must be verified by the user through appropriate testing.

Imperial College London, Imperial College Healthcare NHS Trust and Imperial College London Advanced Hackspace accept no responsibility for use of these designs. Individual mask fitting is a requirement before using.

We would like to acknowledge the below people and institutions:

Dr David M. Miller, Imperial Advanced Hackspace

Mr Harry W. Barnett, Imperial Advanced Hackspace

Alex Martinucci, Ultimaker CREATE Education Project

UK Atomic Energy Authority

More from Hackspace

Discover what’s going on at the Hackspace.

Read our success stories

Work with us