Meet the team

Gwen Mott, Radiation Protection Officer, Imperial College Safety Department

Get in touch

My project

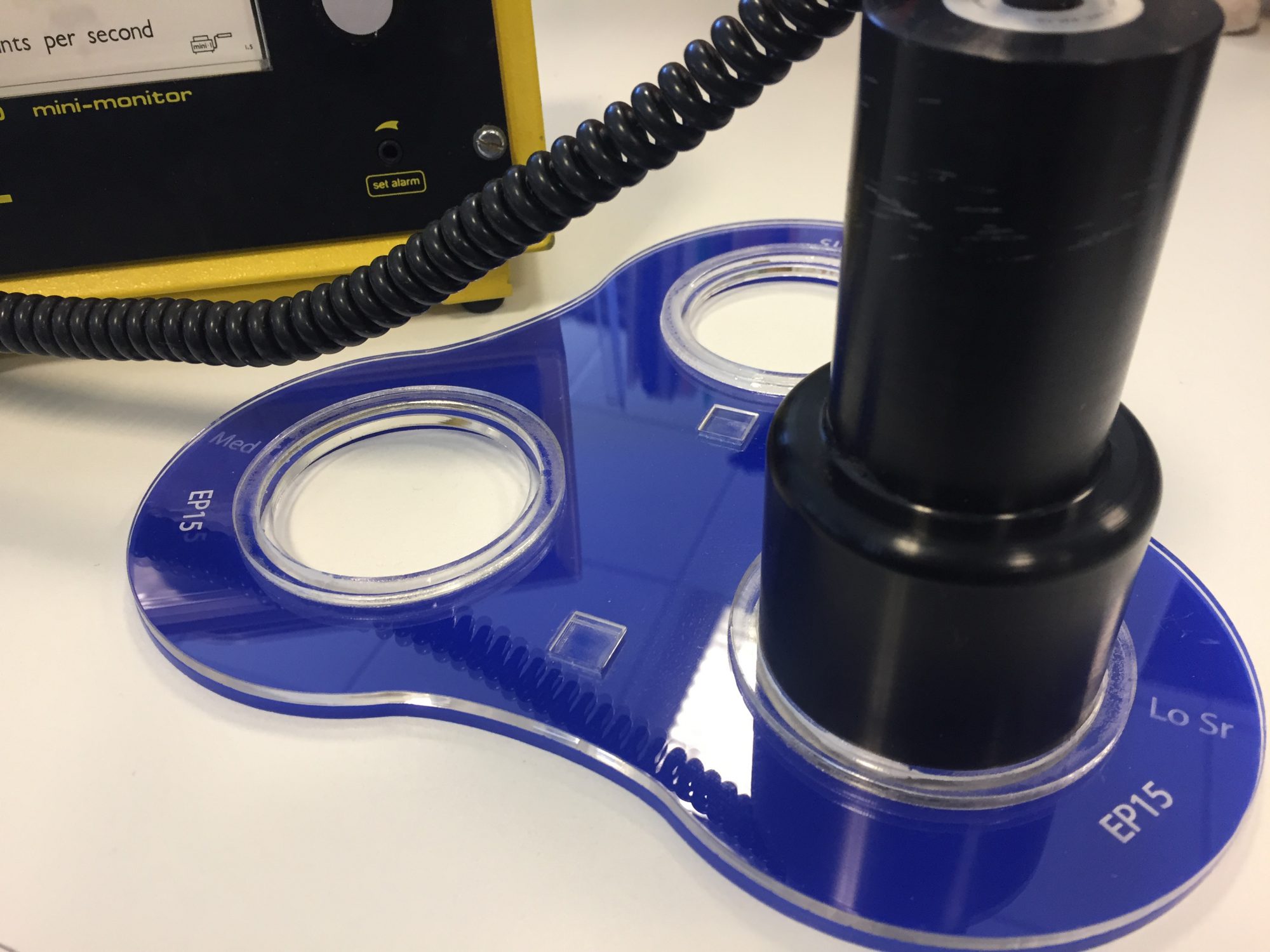

Part of my work within the Radiation Protection Team of the Safety Department involves carrying out calibrations of radiation surface monitors. In order to make the calibration process more consistent, I started exploring the possibilities of making a calibration jig, which would allow the monitor probe to be in the same position over the source for each calibration. Since I was familiar with the use of the laser cutter, I thought this would be a good way to produce the jig and approached the Imperial College Advanced Hackspace to use the equipment there.

Support from Hackspace and the wider Imperial community

The Hackspace team were always happy to help with additional questions about the laser cutter and also the different options to assemble the jig. For example some parts had to be glued together and it was really good to get their input on the different types of glue and what might work best.

The Hackspace is a great place to explore ideas and test different solutions. In my case I could start with cutting some basic shapes to see how they fit and develop my idea from there.

Successes and learning

I think the final calibration jig is definitely a success, and the process of developing it has also taught me some important skills in terms of using the laser cutter that I have used in other projects. It was quite a challenge finding the right glue but, based on advice from the Hackspace, I found one that sets in place. In addition the early version of the jig had only one guide to keep it in the right position, which made it very wobbly. The Hackspace team recommended that I use at least two and that worked perfectly for my purposes.

Advice to aspiring makers, hackers, inventors or entrepreneurs

Don’t be shy and talk to your fellow makers – find out what they are up to!

More from Hackspace

Discover what’s going on at the Hackspace.

Read our success stories

Work with us

Our facilities

News

Catch up on the latest goings-on at Hackspace.

Imperial engineers work with local youth club to design and build e-scooters

Imperial has been working with North Paddington Youth Club to build electric scooters alongside the College's engineers.

When Science and Art collide: White City Sculpture Challenge

The 2022 Sculpture Challenge will provide students the opportunity to collaborate and bring their vision to reality, resulting in the winning sculpture having a permanent presence at the White City Campus.

Hackstarter programme launches to support Imperial’s student makers and creators

Imperial College Advanced Hackspace launches Hackstarter to provide £500 prototype development grants.

© Copyright Advanced Hackspace | Powered by Imperial College London | Privacy Policy I Accessibility Statement | Website by Herd